Precision-Driven Quality Assurance

MeiDe’s tiered validation protocol implements material-to-performance certification across production stages. Utilizing optical emission spectroscopy and helium mass spectrometry, our ISO 17025-accredited labs execute API 600 Clause 8.3 leakage containment tests, achieving ISO 15848-1 fugitive emission Class AH certification thresholds.

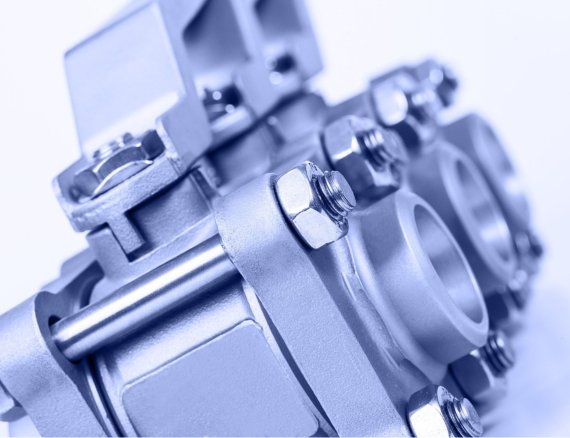

Industrial Valve System Integration

MeiDe engineers operational-grade sealing solutions aligned with API 6DX specifications. Our low-emission actuation packages combine API 622 Annex B sealing validation with ISO 15848-1 torque optimization protocols, maintaining fugitive emissions below 0.5% threshold for ethylene cracking furnace applications.

Valve Engineering Validation Framework

ASME-certified designers develop application-driven valve architectures through finite element analysis, integrating CFD simulation outputs with P&ID data cross-referencing. Final technical packages incorporate ANSI-standard color coding and flange face machining specifications, validating dimensional tolerances through ASME B16.10 checklists.

Configured Valve Production System

Engineered-to-order solutions maintain 30-day order execution timelines through ISO 9001 prototyping stages, executing ASME B16.34 Clause 4.2 pressure envelope verification during factory acceptance trials.

Strategic inventory management stocks API 6D-compliant valves in ASME BPV Code Section VIII warehouses, enabling:

→ Standard orders: 7-day turnaround with API 607 fire-safe certification

→ Emergency MRO supply: 12-hour dispatch for API 6A wellhead components